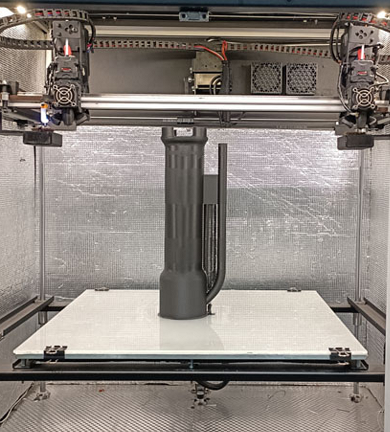

Slice for any model and get the print done with hassle free workflow in at least one of the active tool head.

Auto or Stand-alone mode allows you to choose with the any of the extruder (Left or Right) for your prints with the required material and color, even in the case of breakdown of other extruder.

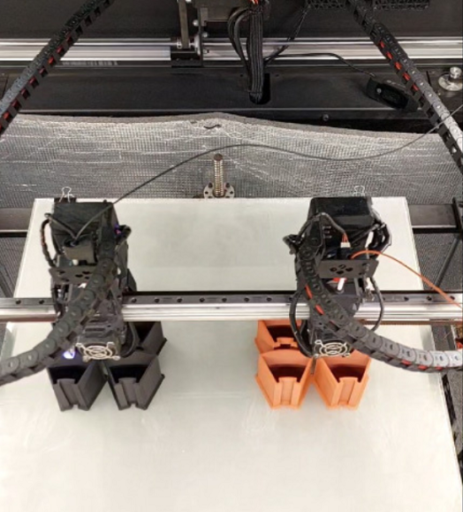

Duplication mode enables the extruder to copy and replicate the master model. The second extruder mimics the main extruder’s movements and slicing parameters, building a synchronized copy in parallel.

This doubles productivity by printing two identical objects simultaneously, ensuring efficient and faster 3D printing with high precision.

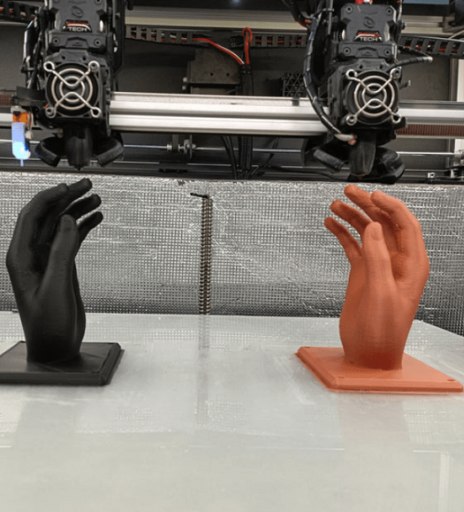

Mirror mode lets the extruder replicate the master model as a mirrored version. The second extruder mimics the main one’s movements and slicing parameters in parallel, creating a symmetrical copy.

This boosts efficiency by allowing the 3D printer to produce an object and its mirrored counterpart at the same time, doubling productivity.

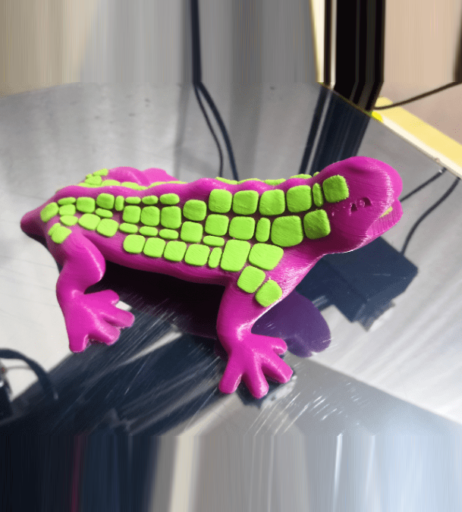

Print a part with two colors to enhance vibrancy and appeal, making designs more eye-catching.

For complex prints, one hotend uses the main material, while the other uses hydro-soluble support material. After printing, the soluble material dissolves in a solvent, leaving the final object with intricate details, smooth surfaces, and clean finishes.

Boost productivity, reduce lead time, and unlock advanced 3D printing capabilities with IDEX technology.

Dual, Duplicate, and Mirror modes enable multi-color, multi-material, and high-efficiency 3D printing.

| Feature | Description |

|---|---|

| No More Oozing or Stringing | Several 3D printers offer Dual Extrusion with two nozzles in a single print head, leading to drawbacks like oozing and limited material use. However, in Independent Dual Extrusion, each nozzle has its own carriage. The inactive nozzle moves to a parking location with a wiping mechanism, ensuring clean and contamination-free prints. |

| 2X Efficiency & Production | The IDEX 3D printer system allows printing with two identical parts simultaneously, doubling production speed and halving lead time. The software automatically copies selected parts, enabling hassle-free workflow, increased productivity, and reduced costs. |

| Multi-Color & Multi-Material Printing | Independent Dual Extruders allow different nozzles to operate at separate temperatures, enabling the combination of various materials like **soluble support material** with a **core material**. This expands design possibilities for **complex geometries**. |

| Dependent vs. Independent Dual Extruders |

Dependent Dual Extruders: Both nozzles move together, often causing print damage due to the inactive nozzle remaining in contact. Independent Dual Extruders: Each nozzle moves separately, preventing damage and allowing greater **material flexibility** and **temperature control**. |