In DP500, "DP" signifies Differential Pressure, indicating a device for measuring pressure differences.

The machine can be tailored according to customer needs:

| Feature | Specification |

|---|---|

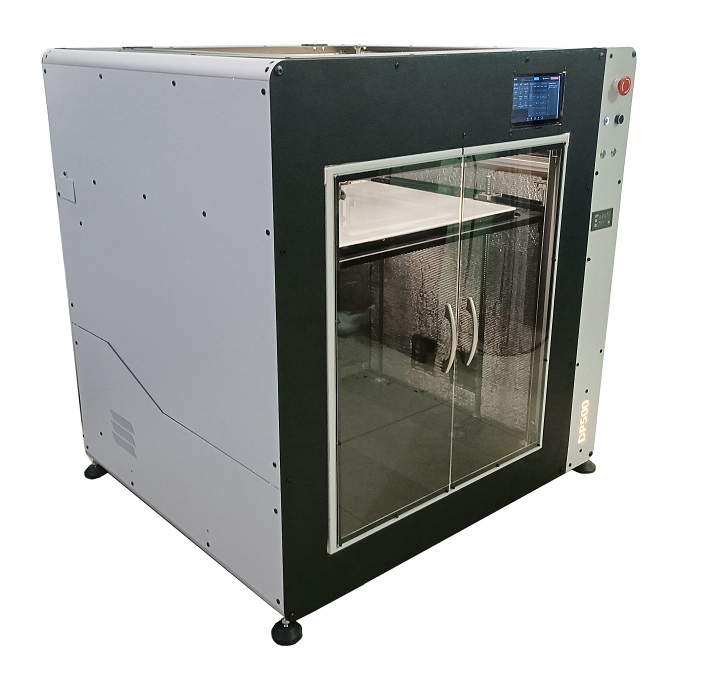

| Print Technology | FFF (Fused Filament Fabrication) |

| Build Volume | 500x500x500mm – Single Mode (Either Left or Right Extruder Separately) 200x500x500mm – Duplicate and Mirror Modes |

| Extruders | Independent Dual Extruder |

| Nozzle Diameter | 0.4mm (Interchangeable from 0.4mm to 1.2mm) |

| Print Resume on Power Outage | No (Recommended to connect with Inverter) |

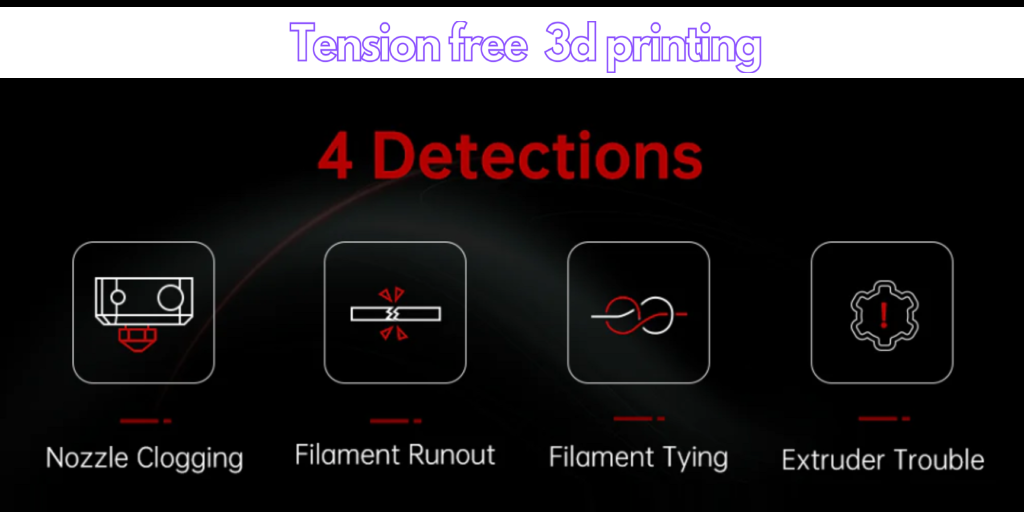

| Filament Run Out / Jam Detection | Yes |

| Build Plate Leveling | Automatic with Bed Leveling Sensor |

| Display Control Panel | Full Touch 7” HDMI Screen |

| Print Speed | Up to 150mm/s * (Varies with different nozzle sizes) |

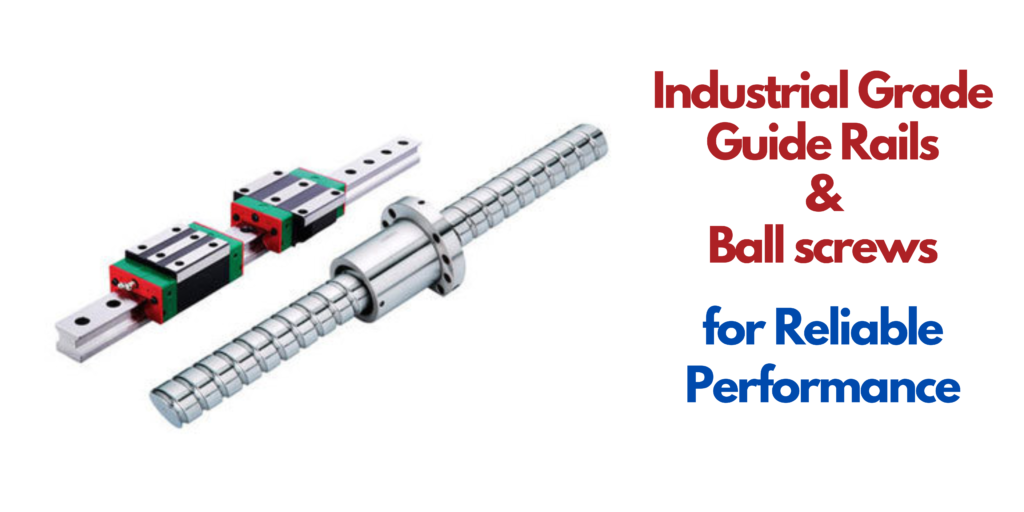

| Mechanics – XY | High-Quality Linear Guides |

| Mechanics – Z | Ball Screws |

| Enclosure | Full Metal Body Enclosure |

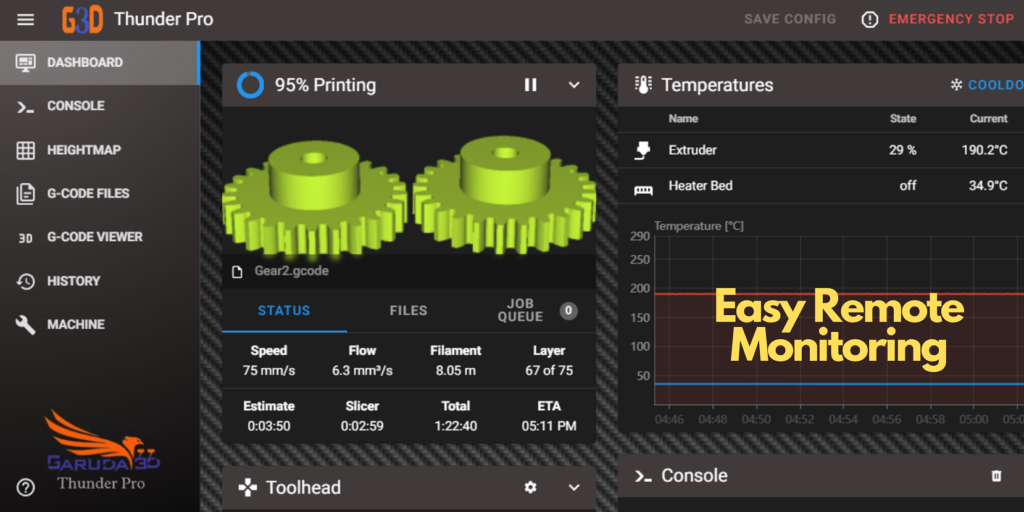

| Camera Monitoring | LAN-Based Camera Monitoring and Control |

| Firmware | Klipper |

| Filter System | HEPA with Activated Carbon |

| Feature | Specification |

|---|---|

| Operating Temperature | Up to 40⁰C |

| Nozzle Temperature | 300⁰C |

| Heating Bed | Aerospace-grade 10mm thick 7075 T6 Aluminum with Faster AC Silicon Heated Bed (Up to 110⁰C) |

| Build Plate | Glass Plate / Spring Steel PEI Magnetic Build Plate |

| Filament Diameter | 1.75mm |

| Supported Filaments | PLA, ABS, PETG, Nylon, TPU, Carbon Fiber, and other Composite Materials* (*Requires hardened steel nozzle.) |

| Filament Support | Open filament from any branded company. |

| Supported File Types | .STL, .OBJ, .AMF |

| Supported OS | Windows, macOS, Linux |

| File Transfer and Connectivity | USB, SD-Card |

| Slicing Software | Cura |

| Printer Control Software | Klipper Main Sail |

| Input | 240V AC, 50Hz |

| Power Rating | From 100W up to 2000W |