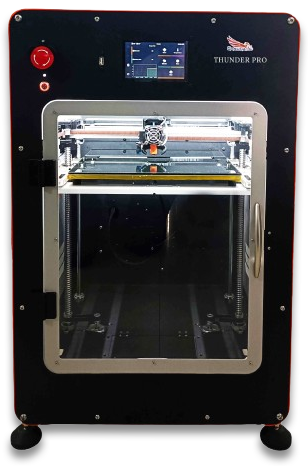

Elevate Your 3D Printing Experience with the Thunde Pro V3 3D Printer

Unlock the next level of 3D printing with the Thunder V3 Pro, a powerhouse designed for speed, precision, and industrial-grade performance. Whether you are an Engineer, Educator, or Small-scale Manufacturer, the Thunder V3 Pro delivers

high-quality prints with unmatched reliability.

Built for versatility and efficiency, this enclosed 3D printer features a large 300x300x300mm build volume, making it ideal for everything from prototyping and functional part production to artistic creations.

Its high-temperature capabilities (300°C hotend & 110°C heated bed) allow you to print with a wide range of materials, including PLA, ABS, PETG, TPU, Nylon, Carbon Fiber, and other composites.

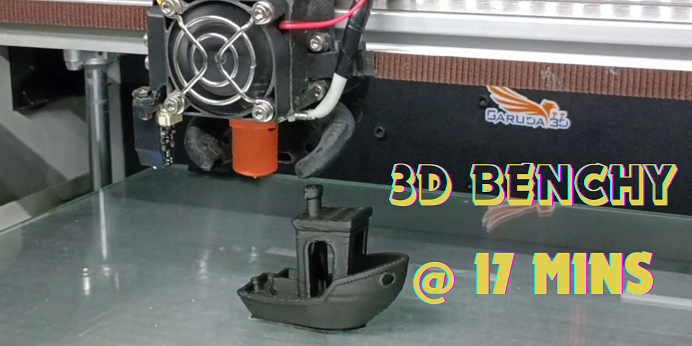

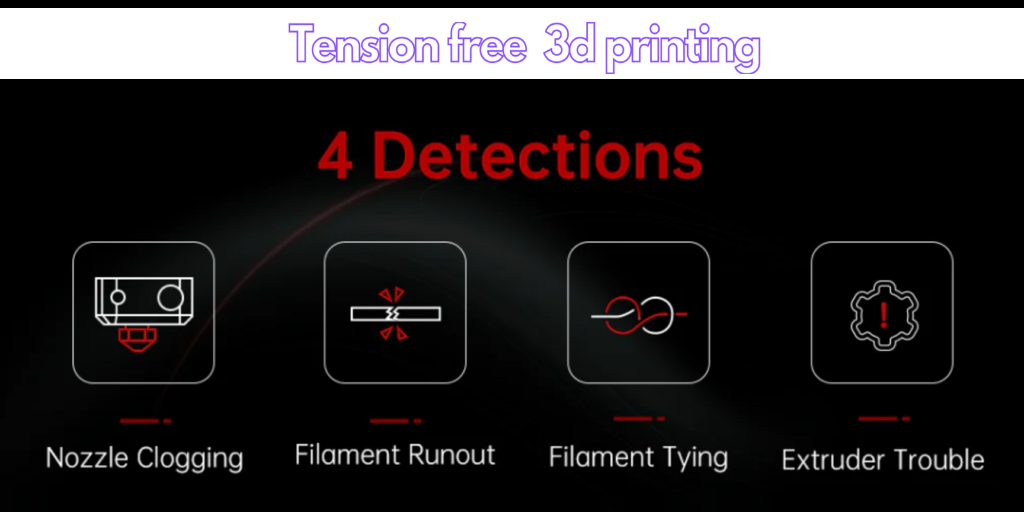

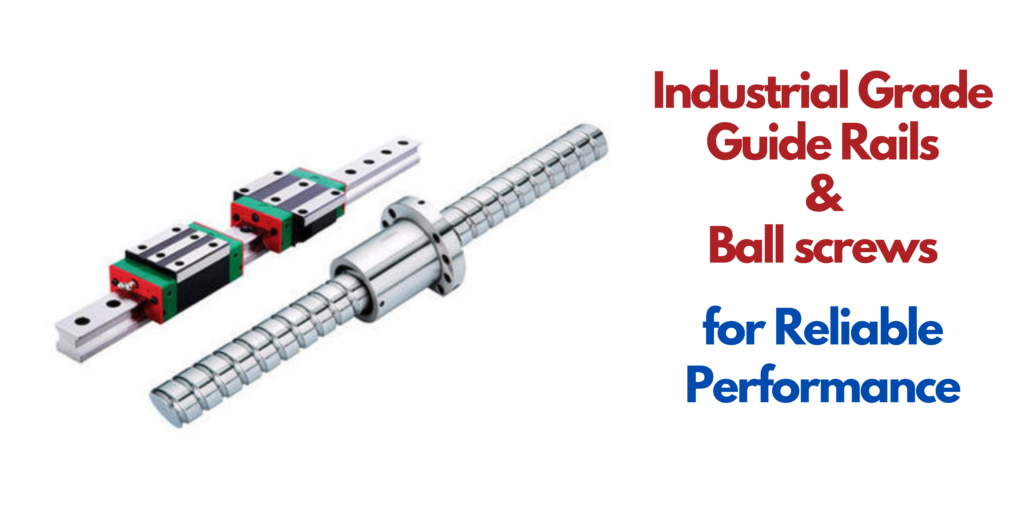

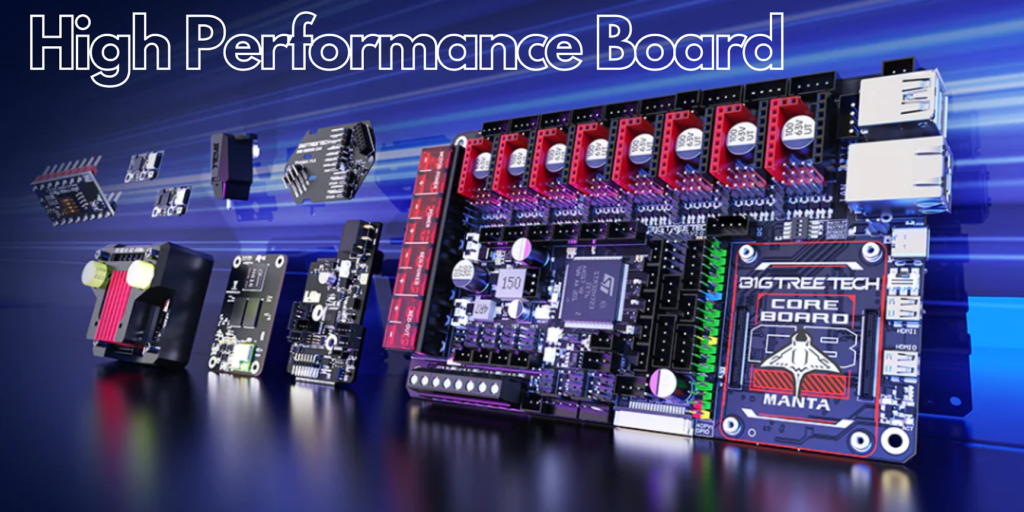

The Thunder V3 Pro is engineered with advanced features such as ultra-fast printing speeds, intelligent failure detection, industrial-grade guide rails & ball screws, and a high-performance 32-bit control board.