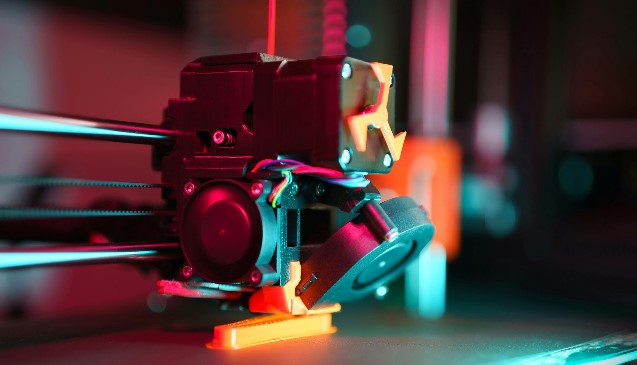

Fused Filament Fabrication (FFF), also known as Fused Deposition Modeling (FDM), is an Additive Manufacturing process that creates Three-dimensional objects by depositing melted thermoplastic filament layer by layer.

This Technology is popular for its affordability, ease of use, and ability to produce both prototypes and functional components.

FFF Technology is very popular because it is economical, simple to operate, and can produce working prototypes as well as final-made components.

The process involves heating and extruding filament through a nozzle that moves along a predefined path to build objects from digital files.

FFF 3D printing continues to evolve, providing new opportunities for industries and hobbyists alike, making it an essential technology in Additive Manufacturing.

Printed with our FFF 3D Printers in different filaments including PLA, ABS, PETG etc. Connect with us for more details

Common materials include PLA, ABS, PETG, TPU, Nylon, and Carbon-fiber-reinforced filaments.

While FFF parts may not be as strong as those made with SLS or Injection Molding, reinforced materials like Carbon Fiber composites improve strength.

Yes, Post-processing like Sanding, Acetone Smoothing, or Painting can improve the appearance and durability of prints.

The accuracy depends on the printer’s specifications, but typical layer resolutions range from 50 to 800 microns.

FDM (Fused Deposition Modeling) is a trademarked term by Stratasys, while FFF (Fused Filament Fabrication) is the generic name for the same technology.

Yes, we provide professional paint finishing services for your 3D printed parts.

Paint Finishing Options:

Post-Processing Services:

Benefits of Paint Finishing:

Turnaround Time:

Pricing: